Loading & Unloading, Machine Tending Applications

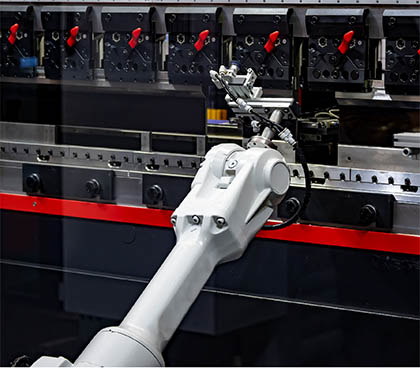

MACHINE LOADING & UNLOADING ROBOTS

Robotic machine loading and unloading automates the demanding, repetitive task of supplying and placing or installing parts onto a machine. Sigma Robotics loading and unloading systems with easy-to-use PLC touchscreens can be configured or reconfigured within minutes by non-technical employees.

Machine loading and unloading operations utilize a robot to load and unload parts on a production machine. These loading robots are equipped with specialized grippers that can securely grasp and deliver parts. These grippers must be designed specifically for the certain part geometry to perform without any failings, and Sigma Robotics is an industry leader in developing, customizing, installing, and maintaining robotic grippers.

Our extensive experience with machining applications highlights the success of robotic automation in a variety of industries. We have designed and installed hundreds of robotic work cells with suitable end effectors and integrated vision systems, creating high performance results and increased production for our customers.

Some of the most common robotic load/unload applications we have designed for our customers:

- CNC Milling

- Turning Centers

- Forging

- Heat Treatment

- Injection Molding

- Glass Beading / Sand Blasting

- Medical & Lab Devices

- Harsh Environment Equipment

For loading and unloading applications, our engineers will help you consider the payload and scope to select the appropriate robot that fits your needs or existing components. We can help you integrate an end-of-arm tool (EOAT) that is compatible with your machine and product. The robot will provide precision and skill for handling parts of different sizes and weights.

Automated robotic loading and unloading is a feasible solution for many small and medium-sized companies, and we can help you select the best system for your needs. Even companies with minimal production will see immediate production gains.

-

Automated machine loading and unloading systems have numerous benefits:

They will provide immediate results and higher performance.

They can load and unload parts with continuous speed and minimal maintenance.

They will maximize the operator’s time and optimize the process flow.

They can process a wide range of part sizes and minimize product damage.

They offer faster and easier configuration without prior programming knowledge.

They will lower investment and increase ROI.

They will provide real-time and future projected outputs.

Loading-Medical

With years of experience, Sigma Robotics exceeds the industry standards for creating customized robotic cells and custom design grippers. We also offer our own, exclusive pneumatic, hydraulic and mechanical standard Sigma Grip® Grippers (EOAT) for robotic applications.