Spot Welding Application

Used with various materials in different industries.

ROBOTIC SPOT-WELDING SOLUTIONS

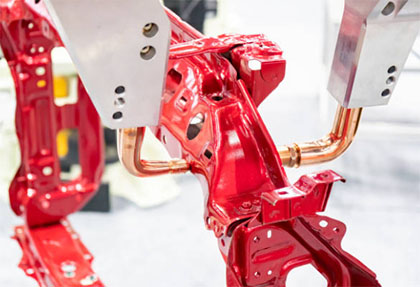

Spot welding has been around for more than 100 years, but it is often a slow and tedious process when done by hand. Robotic spot-welding technology has transformed this process and brought greater efficiency to a variety of industries, from automobile manufacturing to electronics applications, battery manufacturing, and home appliances manufacturing.

Sigma Robotics has helped develop spot-welding systems to bring greater efficiency, precision, and profitability for companies of all sizes.

With years of experience in robotic applications, Sigma Robotics Engineers can help you choose the right spot welding solutions for your company. With high-level functionality such as multistep pressure, work thickness detection, tip wear compensation, servo tip dressers, and gun arm and tip wear compensation, we can help you choose the robotic solutions that will bring immediate results and profitable returns on your investment.

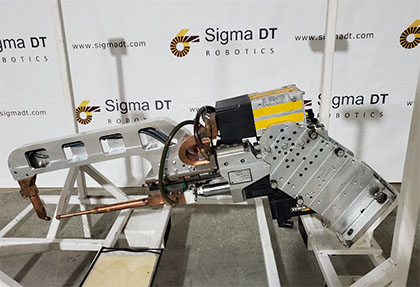

Spot Welding Guns:

- Servo guns are resistance spot-welding guns (RSW) driven by servo motors instead of pneumatic cylinders.

- Pneumatic Guns are resistance spot-welding guns (RSW) driven by pneumatic cylinders.

Robotic spot-welding systems cover an extensive variety of applications, and Sigma Robotics engineers have the expertise to design the optimal robotic welding solutions that your company needs to succeed in today’s competitive marketplace.

Sigma Robotics is an industry leader in automation, customized robotic cells, and custom design grippers. We also offer our own, exclusive pneumatic, hydraulic and servo/mechanical Standard Sigma Grip® Grippers (EOAT) for robotic applications.

Please contact us with questions or to start designing your own customized spot-welding solutions.