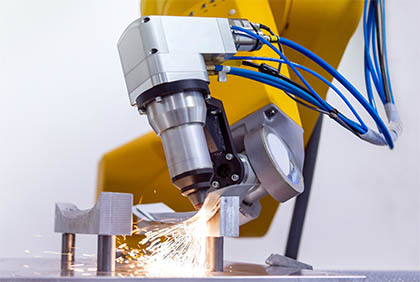

Robotic Laser Welding - Laser / Plasma Cutting

Used with various materials on different industries.

- Robotic Laser Welding

- Robotic Laser Cutting

- Robotic Plasma Cutting

Robotic Laser Welding

There are many advantages to upgrading from manual welding to robotic laser welding. While traditional welding processes use a lot of manpower, energy, and resources, laser welding processes weld with greater accuracy and precision—while using less energy and requiring less repair.

Whether joining pieces metal or thermoplastics, laser beam welding uses an intensely focused heat source to create accurate welds and increase welding rates. As the power of the laser beam increases, so the thickness of material that can be welded increases. For example, a 3 kW CO2 laser can weld steel up to ¼-inch, while a 25 kW CO2 laser can weld 1-inch thick steel.

Sigma Robotics integrates different brands of well-known laser resonators into a robotic laser welding system. Our engineers have designed robotic laser welding systems for a variety of industries, and they have the expertise to optimize the solutions your company needs to compete in today’s competitive marketplace.

Robotic Laser Cutting

Just like robotic welding is a superior technique than traditional welding, laser cutting offers many advantages over traditional saw cutting or mechanical milling and cutting. Laser cutting offers versatility and can be used for a range of thicknesses and a variety of materials. From steel and stone to plastics and glass, laser beam cutting is precise, smooth, and cost efficient.

Laser cutting is a non-contact process and is frequently used with plate-shaped materials. But Sigma Robotics solutions can be customized to cut almost any shape or material to a variety of thicknesses.

Advantage of Robotic Laser cutting

Laser technology offers a non-contact, thermal cutting process with the following advantages:

- Clean-cut edges

- Fast process speeds with 3D laser cutting

- Flexibility of almost any 3D object surface cutting

- Synchronized multi-cutting-head laser applications

- Large-size (track-integrated) 3D laser systems

- No workpiece distortion

- Optimal material utilization

Robotic spot-welding systems cover an extensive variety of applications.

Robotic Plasma Cutting

The main differences between robotic plasma cutting and robotic laser cutting systems are the cost of systems and the quality of the material edge finish.

Plasma Cutting options include:

- High-Definition Plasma Cutting

- Regular Plasma Cutting

Please contact us for more details and our Engineering solutions.

Sigma Robotics is an industry leader in automation, creating customized robotic cells and custom design grippers. We also offer our own exclusive pneumatic, hydraulic and servo/mechanical standard Sigma Grip® Grippers (EOAT) for robotic applications.